Welcome to Part 2 of 3 of our Dust Generation Series.

In this part, we will go over and revise how the overlap of a blade plays a huge role in dust generation.

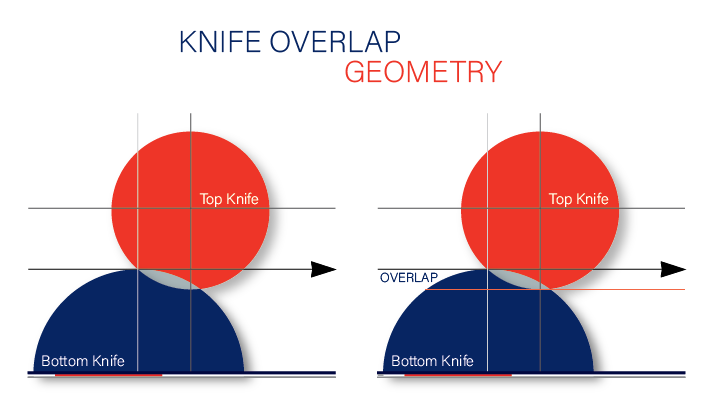

First, let’s clarify what overlap means.

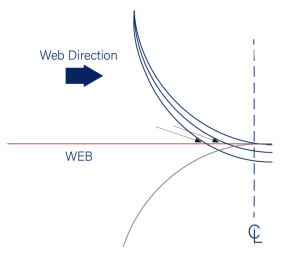

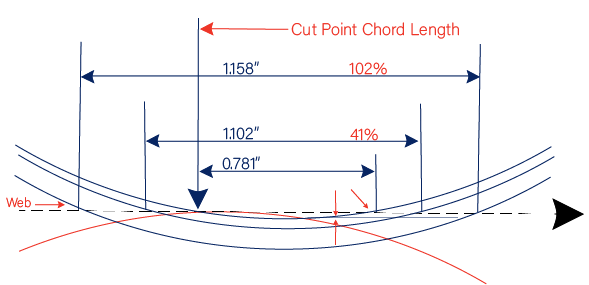

As we discussed in part 1, for shear slitting to occur, there needs to be a “Cut Point” and this requires some overlap of the two knife blades. Overlap is defined as the distance the top knife is set below the tangential surface of the bottom knife. Overlap must resist dynamic forces while minimizing the web material contact area. This is accomplished by reducing the “travel chord” between the top and bottom knife. Just to clarify, the “travel chord” is defined as the distance the slit web must move in contact with the beveled knife edge.

Excessive Top Knife Overlap is the Single Worst Set-Up Mistake to Make.

As there are three significant ways excessive overlap contributes to dust generation when slitting with a tangential web path. They are:

- Increased web travel chord distance.

- Change of the Cut Point.

- Wider blade width.

Excessive Overlap

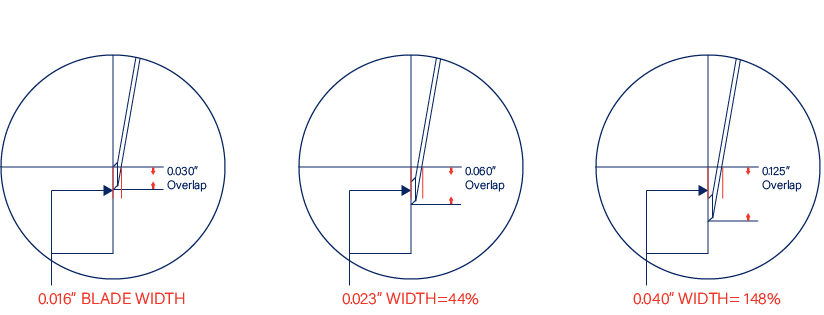

But, what is too much overlap? Well, as a general guideline for most applications, we recommend having an overlap of 0.030-0.040”. As mentioned in the previous list, the first and most significant way that dust generation is increased is by the increased web travel chord that the material experiences with an excessive overlap. As even a small amount of 0.020” excess overlap can lead to a 41% increase in chord length! If we continue and exceed the recommended overlap setting by another 0.060” it will result in an increased chord length of 102%!

Geometry Set-Up

Geometry Set-Up

It is important to mention that with a wrapped web path only points 1 and 3 from the list above contribute to slitting dust, as with this geometry set-up, the cut point can be in any position where the web is in contact with the bottom knife. Although, it is still very important that the blade is held rigidly in place as otherwise, this could make the knife lose contact with the bottom knife and web and it could create a web rupture.

Knife Width or Area of Blade Contact with the Material

As mentioned before, we want to minimize the area of contact from the material and the blade while still delivering rigidity and a constant cut point. But, by increasing the overlap we are widening the blade of the width (and the contact area as well). As with a 0.020” excess overlap, the blade width is increased by 44% and an excess overlap 0.060” will result in an increased chord length of 148%! This may not seem large, but when you consider that a wider area results in increased web drag on the knife, that may lower the web speed more than what was desired, which in turn increases the dust-generating from the application.

Too little overlap can lead to “knife jump”. This is when run-out, or a lessening of air pressure, causes the top knife blade to lift over and onto the top of the bottom knife blade. Immediately the top knife will be destroyed. Also, because of the continuing horizontal stroke, when the top knife jumps a carbide inserted bottom knife, it can slide into the carbide/tool steel adhesive joint and slice the carbide ring off, destroying both tools.

In the previous section, we have discussed in-length how the run-out affects dust generation. But how can you ensure a proper run-out and blade profile? Check out part 3 of 3 on dust generation to learn how to overcome these issues.

Geometry Set-Up

Geometry Set-Up